Ohio firm uses TAAF matching funds to speed New Product Development

“Our experience with GLTAAC has been extremely beneficial to our business. The program is really making a positive impact on our company.”

— Kevin Lee, President

Background

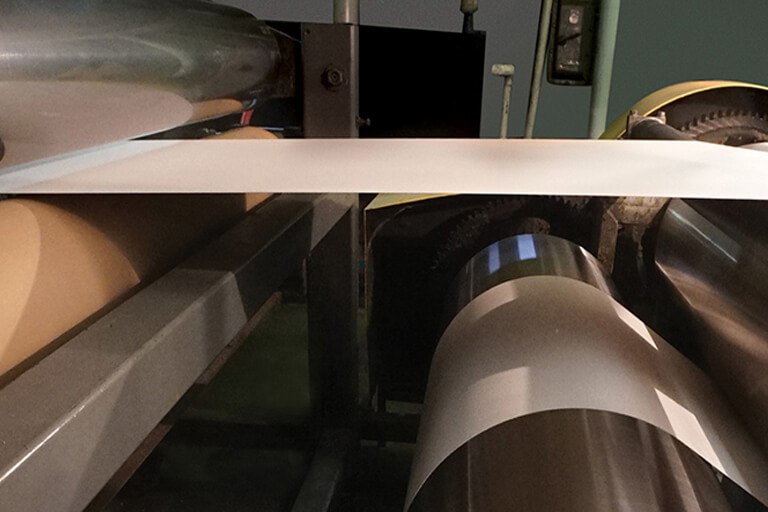

Buckeye Fabric Finishers (now B&E Fabric Finishers) was founded in Coshocton, Ohio in 1922. Customers have long looked to B&E for its capabilities and specialized coatings. So, when a key ingredient for one of its customized coatings became unavailable, the company was faced with the possibility of losing long time customers.

Buckeye Fabric Finishers (now B&E Fabric Finishers) was founded in Coshocton, Ohio in 1922. Customers have long looked to B&E for its capabilities and specialized coatings. So, when a key ingredient for one of its customized coatings became unavailable, the company was faced with the possibility of losing long time customers.

Approach

B&E needed to find a way to make the coating without the old ingredient. To help them respond to the situation as quickly as possible, B&E turned to a local consultant with in-depth experience in the chemical and coatings industry. GLTAAC worked with the company and the chemist to scope and contract the needed project, then funded 50% of its cost via the TAAF program.

The consultant researched B&E’s entire process, evaluated potential alternatives, then developed and tested multiple new formulations.

Results

The result was a successful reformulation of the coating that fully meets their customers’ specifications. All components in the new formula are readily available, significantly easier to use, and less expensive. Additionally, the consultant assessed B&E’s inventory of now-obsolete raw materials, developed a disposal plan, and oversaw their removal.

Kevin Lee, President of B&E Fabric Finishers, states: “Our experience with GLTAAC has been extremely beneficial to our business. The program is really making a positive impact on our company.”