Precise Tooling Uses TAAF to Implement

Game-Changing Technology

“Thanks to GLTAAC’s assistance, we were able to take advantage of the full $75,000 in matching funds to quickly implement a strategic initiative which gives Precise Tooling Solutions a competitive advantage against foreign imports.” – Don Dumoulin, CEO & Owner

Background

Precise Tooling Solutions is a specialty manufacturer in central Indiana that builds and repairs injection tooling for the plastics industry. In particular, the company is recognized for its expertise building and servicing tight-tolerance optical lighting tools and thermoset molds for the automotive, aerospace, medical device and consumer goods industries. In recent years, however, low-cost tools from China have flooded the market, severely impacting the domestic tool building industry.

To survive in this environment, successful injection tool builders have employed tactics such as reducing lead times, optimizing their design and production capabilities, being highly attentive to customer needs, offering add-on products & services, and, of course, containing costs.

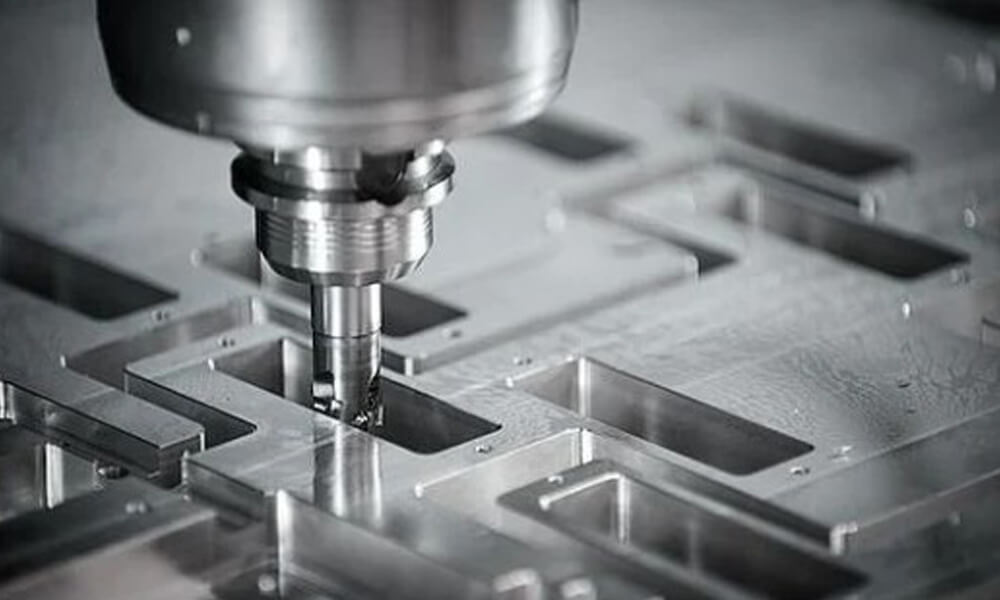

Under the leadership of Don Dumoulin, who bought the business in 2013, Precise Tooling was already doing many of these things. The company had built its reputation on short lead times and excellent on-time delivery performance. With Don in the lead, Precise Tooling’s management team pivoted their business model by viewing mold repair as a core component of their business rather than just an add-on service. They also began building adjustable-height workbenches and lift tables to capitalize on the growing utilization of operator-friendly ergonomic equipment in the manufacturing sector. More broadly, the company embraced advanced 5-Axis machining and support systems for their highly-skilled craftsmen. As a result, Precise Tooling was selected by MoldMaking Technology for the prestigious 2020 Leadtime Leader Award, a program that recognizes top tool manufacturers in the U.S. and Canada.

Despite these significant investments and improvements, Precise Tooling was still losing ground to imported tooling. That is just the reality of competing in a global economy for many small manufacturers today.

The company could not be happier with its results. Sales in 2014 were up 51% over 2011 (and employment was up 23%). Growth has continued thru 2015. This success was due to more than just the TAAF program, of course, but GLTAAC’s involvement was a key factor—both the funding and the assessment and planning process.

Approach

Precise Tooling is committed to continuous improvement, and shortly before engaging with the GLTAAC, they identified a potential game-changing software package from VISI. So, when the TAAC visited Precise Tooling, Don was confident he knew the one project which could dramatically enhance the competitive position of his company. After learning more, GLTAAC agreed.

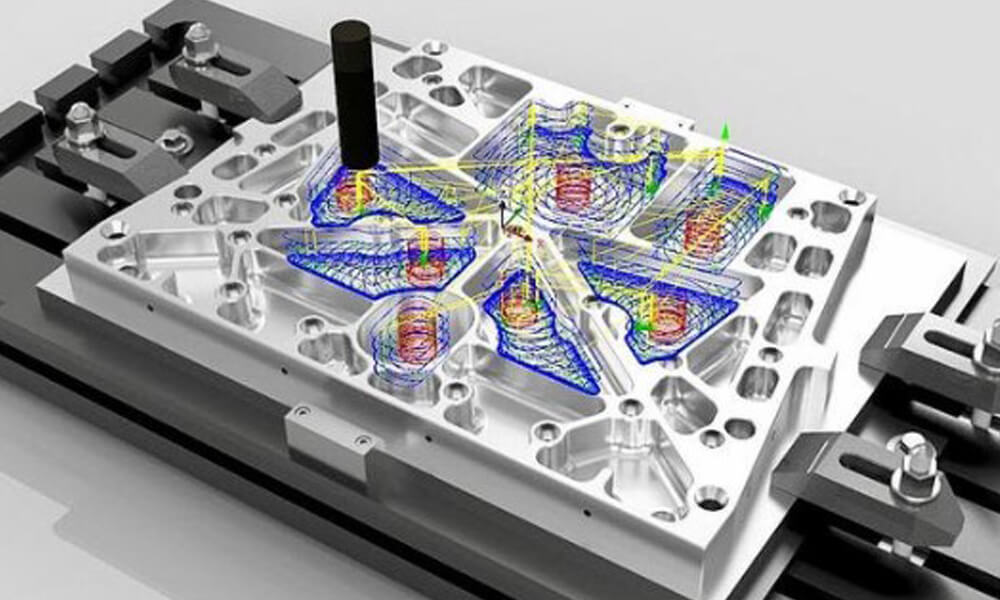

VISI software links a manufacturing firm’s design process to its production equipment. It does this by translating design files (CAD) directly into the machine language (CAM) that controls machining operations. Integrating this software into a company’s operational process eliminates errors, while reducing the time needed to design and build the customer tools by several weeks – both of which lower costs and reduce lead times. In short, implementing VISI software could significantly enhance one of the company’s key competitive advantages over imports.

Unfortunately, implementing such VISI software is expensive. The installation and training costs alone exceeded $150K, which seemed prohibitive in light of the economic slowdown caused by the COVID pandemic.

That is where GLTAAC stepped in. The TAAC developed an Adjustment Plan for Precise Tooling that focused on a single project—the VISI implementation. It was then able to support the project by paying 50% of installation and training costs. TAAF co-funding made the project feasible because it reduced the Company’s cash outlay by $75k.

Results

Precise Tooling integrated the VISI software into their operational processes throughout the 4th quarter of 2020. Initial results in the 1st quarter of 2021 indicate that design and programming times are down 35 to 65% allowing Precise Tooling to be even more competitive in a challenging marketplace.

According to Kevin Rucinski, the GLTAAC Senior Project Manager who worked with the company, “Most of our clients use the program to do 3–5 projects, sometimes more. But in Precise Tooling’s case, it was clear that a VISI implementation had the potential to push the company’s competitive position to the next level—so that is what we helped them do. That is why the TAAF program works—it can fit to the specific needs of each client company and customized to make whatever improvements make sense for them, given their own unique situation.”